Pengrowth

PTFE Directional Film PTFE Oriented Films Roll Ultra-thin Orientation Film Thickness 0.03mm to 0.1mm

PTFE Directional Film PTFE Oriented Films Roll Ultra-thin Orientation Film Thickness 0.03mm to 0.1mm

Couldn't load pickup availability

This film is made from suspended polytetrafluoroethylene (PTFE) resin. The resin is first molded, sintered, and cooled to form a blank, and then it is turned and calendered. The turned film is non-oriented. The non-oriented film is stretched and oriented at a high temperature, which endows the film with better physical properties and processing performance. After the calendering process, it becomes an oriented film.

Material: Polytetrafluoroethylene(PTFE)

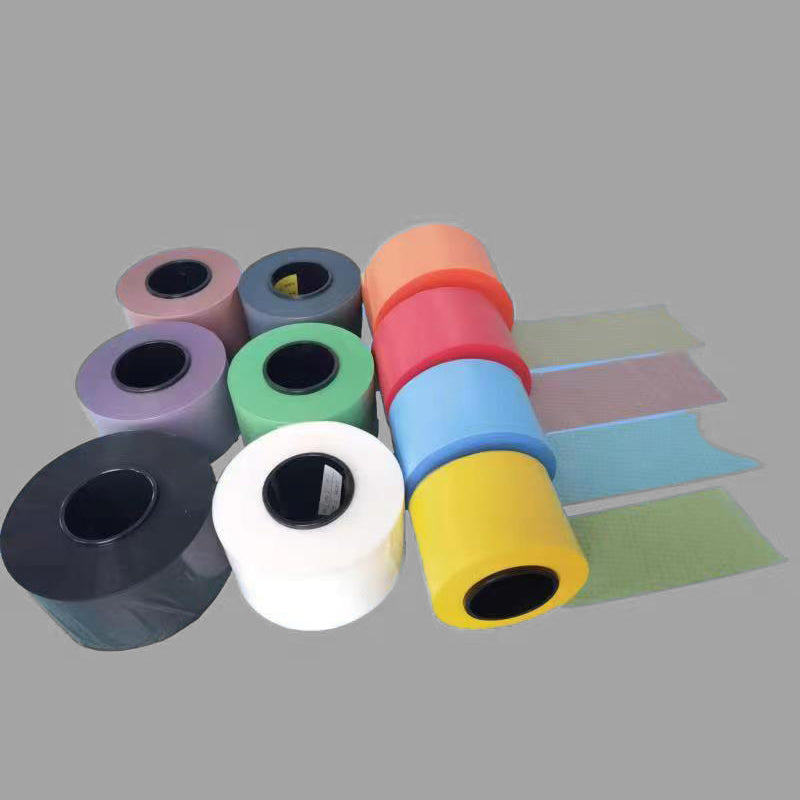

Color: Natural color, Red, Green, Blue, Orange, Gray, Purple, Brown, Black, White.

Size: Thickness: 0.03-0.1mm

Width: 60mm/90mm/300mm

Length: Customizable (any length)

Custom thickness or size please contact us. Film will be supplied in continuous lengths unless advised otherwise.

Appearance

The film is curled and flat, the end face is neat, and the film surface is free of creases, cracks, holes, mechanical damageand other surface defects that affect the use.

Performance Characteristics

The weight is usually 3-3.5kg/roll without joint. We can make 14kg /roll without joint.

lf the disc diameter is greater than 200mm, generally, no trimmingis required, and the end face is not flat. The common pipe cores are67mm and 78mm.

The non directional film is made by turning the blank with lathe. Also known as turning film(skived film).

The orientation degree of semidirectional film and directional filmis 1.1-2.0, and the orientation degree of directional film is more than2.0.

The higher the orientation, the higher the tensile strength, the lowerthe elongation at break and the higher the breakdown strength.

Determination method of orientation: the sample is 15cm long Heat the sample in an oven until it is transparent (above 327 Cgenerally 360 ℃-380 ℃), keep it warm for 15min, then slowly cool itto about 260 ℃, take it out, and cool it to room temperature. Theratio of the length of the sample before and after heating is the orientation.

It has excellent chemical stability, an extremely low coefficient of friction, good heat resistance, high electrical insulation, and outstanding weather resistance.

- Electronic and electrical field (insulation layers of wires and cables, insulating gaskets of electronic components).

- Chemical industry (sealing of pipelines).

- Automotive field (sealing parts of automobile engines, wear-resistant coatings for automobile interiors).

- Aerospace field (sealing parts of the hydraulic systems of aircraft, insulating materials for aerospace electronic equipment, etc.).

- Food, medical and other fields (non-stick coatings for food packaging, moisture-proof and oxygen-barrier layers for medical packaging, etc.).

Share